The Continental O-200 Parts Manual is a comprehensive guide for the maintenance, repair, and overhaul of Continental O-200 series engines, covering models C75, C85, C90, and O-200. It provides detailed parts listings, assembly diagrams, and technical specifications to ensure accurate repairs and upgrades. This manual is essential for mechanics, technicians, and enthusiasts working with these engines, offering a clear and organized reference for all maintenance needs.

1.1 Overview of the Continental O-200 Engine

The Continental O-200 engine is a four-cylinder, horizontally opposed, air-cooled aircraft engine, renowned for its reliability and efficiency. Producing 100 horsepower, it powers various small aircraft, including the Cessna 150 and Piper PA-28. Designed for simplicity and durability, the O-200 features a direct-drive propeller system and a dual magneto ignition. Its compact design and lightweight construction make it ideal for training aircraft and recreational flying. With a long service history, the O-200 remains a trusted choice for aviation enthusiasts and professionals, offering consistent performance and minimal maintenance requirements.

1.2 Purpose of the Parts Manual

The Continental O-200 Parts Manual serves as an essential reference guide for identifying, ordering, and installing engine components. It provides detailed part numbers, descriptions, and assembly diagrams to facilitate accurate maintenance and repair. The manual ensures compliance with manufacturer specifications, guaranteeing safety and performance. It is tailored for mechanics, technicians, and enthusiasts, offering a comprehensive resource for overhaul procedures, routine maintenance, and troubleshooting. By adhering to the manual’s guidelines, users can extend engine longevity and uphold operational integrity, making it indispensable for anyone working with the O-200 engine.

1.3 Structure and Organization of the Manual

The Continental O-200 Parts Manual is structured to provide easy navigation and quick access to critical information. It begins with an introduction, followed by a detailed table of contents. The manual is divided into sections, including group assembly parts lists, oversized and interchangeable parts, and customer specifications; Each section is logically organized to guide users through maintenance, repair, and overhaul processes. Clear indexing and cross-referencing ensure users can locate specific parts and procedures efficiently. The manual also includes visual aids like diagrams and charts to enhance understanding, making it a user-friendly resource for technicians and enthusiasts alike.

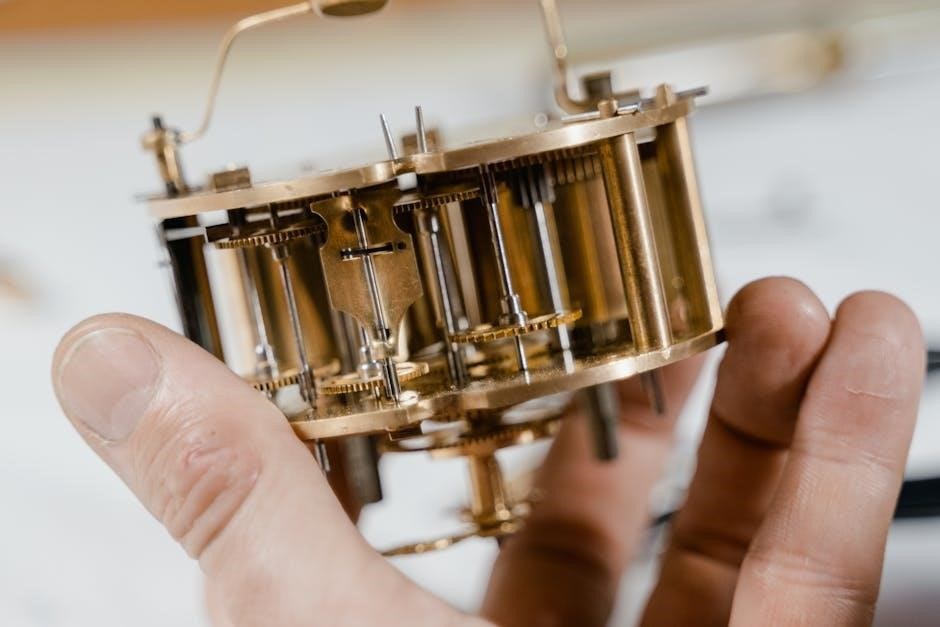

Continental O-200 Engine Overview

The Continental O-200 is a four-cylinder, air-cooled aircraft engine known for its reliability and performance in small aircraft. It offers efficient power output and durability.

2.1 Key Features and Specifications

The Continental O-200 engine is a four-cylinder, spark-ignited aircraft engine producing 100 horsepower at 2,750 RPM. It features a displacement of 201 cubic inches and is air-cooled for reliability. Designed for small aircraft, the O-200 is lightweight and compact, making it ideal for applications requiring efficient power. The engine operates on 100LL avgas and is known for its fuel efficiency and durability. Detailed specifications, including part numbers and torque values, are outlined in the parts manual, ensuring precise maintenance and repair. Its simplicity and robust design have made it a popular choice for general aviation.

2.2 Applications of the O-200 Engine

The Continental O-200 engine is widely used in small, single-engine aircraft, including popular models like the Cessna 150 and Piper J-3 Cub. Its lightweight design and fuel efficiency make it ideal for training aircraft, bush planes, and recreational flying. Additionally, the O-200 is commonly used in experimental and homebuilt aircraft due to its reliability and ease of maintenance. The engine’s versatility extends to various aviation applications, offering consistent performance in diverse operating conditions. Its widespread adoption underscores its reputation as a dependable powerplant for general aviation needs, balancing power output with operational economy.

2.3 Historical Background and Development

The Continental O-200 engine was first introduced in the 1950s, becoming a cornerstone of small aircraft propulsion. Developed by Teledyne Continental Motors, it evolved from earlier C-series engines, inheriting their proven design while incorporating advancements in materials and engineering. The O-200 was designed to be lightweight, fuel-efficient, and reliable, making it an ideal powerplant for training aircraft and general aviation. Over the years, its reputation for durability and performance solidified its place in aviation history. The engine has undergone continuous refinement, with updates focusing on improving efficiency and reducing maintenance complexity, ensuring its longevity in the aviation industry.

Illustrated Parts Catalog

The Illustrated Parts Catalog provides a detailed visual and technical reference for identifying and ordering parts for the Continental O-200 engine, including group assemblies and components.

The Illustrated Parts Catalog serves as a foundational reference for identifying and procuring parts for the Continental O-200 engine. It provides a structured overview of the engine’s components, organized by group assemblies and individual parts. This section introduces users to the catalog’s layout, highlighting key features such as detailed diagrams, part numbers, and interchangeability notes. Designed for mechanics, technicians, and enthusiasts, the catalog simplifies the process of locating and ordering the correct parts for maintenance, repair, and overhaul tasks. It ensures clarity and accuracy, making it an indispensable tool for anyone working with the Continental O-200 engine.

3.2 Group Assembly Parts List

The Group Assembly Parts List in the Continental O-200 Parts Manual organizes components into logical assemblies, simplifying identification and procurement. Each assembly, such as crankcases or cylinder heads, is detailed with part numbers, descriptions, and quantities. This structured approach ensures technicians can quickly locate and order the necessary parts for maintenance or overhaul. The list also highlights interchangeable and oversized parts, aiding in compatibility checks. By categorizing parts into assemblies, the manual streamlines the repair process, reducing confusion and ensuring accuracy. This section is invaluable for anyone performing routine maintenance or major overhauls on the Continental O-200 engine.

3.3 Oversized and Interchangeable Parts

The Continental O-200 Parts Manual details oversized and interchangeable parts, crucial for engine repairs and overhauls. These parts, such as pistons or bearings, are designed to accommodate wear tolerances or damage. The manual lists interchangeable components across O-200 models, enabling cost-effective repairs by using existing parts. Tables and diagrams specify compatible parts, ensuring technicians can identify suitable replacements without cross-referencing multiple sections. This section is vital for maintaining engine performance and extending service life, emphasizing the importance of proper part selection to meet original specifications and operational standards. It simplifies the repair process, reducing downtime and ensuring reliability. Detailed part numbers are provided for clarity.

Engine Models Covered in the Manual

The manual covers Continental O-200 series engines, including C75, C85, C90, O-200-A, and O-200-B models, providing detailed parts and specifications for each engine variant.

4.1 C75 Series Engines

The C75 series engines are four-cylinder, spark-ignited powerplants designed for light aircraft. With a displacement of 5.00 cubic inches, they deliver 75 horsepower at 2,800 RPM. Known for their reliability and efficiency, these engines are widely used in training aircraft and small general aviation planes. The manual provides detailed specifications, parts lists, and maintenance guidelines for the C75, ensuring proper operation and longevity. It covers essential components like cylinders, pistons, and crankcases, making it an invaluable resource for mechanics and operators of these engines.

4.2 O-200-A and O-200-B Models

The O-200-A and O-200-B are four-cylinder, spark-ignited engines designed for light aircraft, delivering 100 horsepower at 2,800 RPM. Both models share similar design features, including air-cooled cylinders, a magnesium alloy crankcase, and a dual magneto ignition system. The O-200-A is typically used in trainer aircraft, while the O-200-B is often installed in small general aviation planes. These engines are known for their reliability, fuel efficiency, and ease of maintenance. The manual provides detailed specifications, parts listings, and service procedures for both models, ensuring optimal performance and longevity in various aviation applications.

4.3 Differences Between O-200-A and O-200-B

The primary differences between the O-200-A and O-200-B models lie in their engine mount provisions and applications. The O-200-A features a shorter crankshaft and is typically mounted with a straight engine mount, making it ideal for tractor-type aircraft configurations. In contrast, the O-200-B has a longer crankshaft and is designed for pusher-type aircraft, utilizing a “lord mount” assembly. These variations ensure compatibility with specific airframe designs while maintaining the same core engine performance characteristics. Both models share identical internal components and require similar maintenance procedures, simplifying parts interchangeability and serviceability.

Maintenance and Overhaul

Regular inspections, timely part replacements, and adherence to manufacturer guidelines ensure optimal engine performance. Detailed procedures for routine maintenance and major overhauls are outlined, along with gasket sets usage.

5.1 Routine Maintenance Procedures

Routine maintenance is crucial for ensuring the longevity and performance of the Continental O-200 engine. Daily inspections should include checking oil levels, fuel, and general engine condition. Weekly, inspect spark plugs, air filters, and ignition systems for wear or damage. Monthly, perform oil and filter replacements, and check cylinder compression. Annual maintenance includes overhauling the carburetor and inspecting the magneto. Always use genuine Continental parts for replacements to ensure compatibility and performance. Adhere to manufacturer guidelines for torque specifications and lubrication. Regular maintenance helps prevent unexpected failures and ensures safe, efficient engine operation.

5.2 Major Overhaul Procedures

A major overhaul of the Continental O-200 engine involves a thorough disassembly, inspection, and replacement of critical components. Begin by removing the cylinder heads, pistons, and crankcase. Inspect for wear on crankshafts, camshafts, and bearings. Replace gaskets, seals, and any damaged parts using genuine Continental components. Reassemble the engine, ensuring proper torque specifications. Perform a compression test and magneto check post-overhaul. Document all repairs and adhere to factory guidelines for compliance. Regular overhauls extend engine life and ensure reliable performance, maintaining safety and efficiency in aircraft operations.

5.3 Gasket Sets and Sealing Solutions

Gasket sets for the Continental O-200 engine are essential for ensuring proper sealing and preventing leaks during operation. The manual provides detailed specifications for gaskets, seals, and O-rings, including intake manifold, cylinder head, and crankcase gaskets. Major overhaul gasket sets are available, covering all critical sealing points. Proper installation requires adherence to torque specifications to avoid damage or leakage. Genuine Continental parts are recommended for reliability and durability. Regular inspection and replacement of gaskets are crucial for maintaining engine performance and preventing costly repairs. The manual also outlines compatible sealing solutions for various engine models and configurations.

Parts Identification and Interchangeability

This section provides detailed guidance on identifying Continental O-200 engine parts and determining their interchangeability. Part numbers, specifications, and compatibility are clearly outlined for accurate replacement and maintenance.

6.1 Understanding Part Numbers

Understanding part numbers is crucial for identifying and ordering correct components for the Continental O-200 engine. Each part number is a unique identifier, often consisting of a combination of letters and numbers. For example, parts like C75, C85, and O-200-A/B have distinct designations, reflecting their specific applications and specifications. The manual provides a detailed breakdown of part number structures, enabling users to decipher their meanings. This section also explains how to cross-reference parts with engine models and specifications, ensuring compatibility and accuracy in maintenance and repairs. Proper identification prevents mismatches and ensures compliance with manufacturer standards.

6.2 Interchangeability of Parts

Interchangeability of parts for the Continental O-200 engine is detailed in the manual to ensure compatibility and avoid mismatches. While some components like gaskets and bearings may be interchangeable across models, others, such as crankshafts or cylinder heads, are model-specific; The manual highlights differences between O-200-A and O-200-B engines, emphasizing parts that cannot be swapped. Proper identification using part numbers and customer specifications is essential. This section helps users understand which parts can be shared and which require model-specific solutions, ensuring safe and effective repairs. Always consult the manual before ordering or installing parts to maintain engine performance and longevity.

6.3 Customer Specifications and Variations

The Continental O-200 parts manual addresses customer-specific variations and unique engine configurations. It provides detailed listings of parts tailored to individual customer requirements, ensuring compatibility and performance. Variations may include custom-engineered components or modifications for specific applications. The manual outlines differences in part numbers and assembly specifications, helping users identify the correct parts for their engine model. This section is crucial for maintaining compliance with original design standards and ensuring optimal engine operation. By adhering to these guidelines, users can avoid mismatches and maintain the integrity of their Continental O-200 engine, whether for routine maintenance or major overhauls.

Troubleshooting and Common Issues

This section provides guidance on identifying and resolving common issues with the Continental O-200 engine, including diagnostic procedures and repair recommendations to ensure optimal performance.

7.1 Common Problems and Solutions

Common issues with the Continental O-200 engine include oil leaks, magneto failures, and cylinder wear. Oil leaks often occur at the engine’s case halves or valve cover gaskets, requiring seal replacement. Magneto problems can cause ignition malfunctions, necessitating spark plug and wiring checks. Cylinder wear may lead to reduced compression, requiring piston and ring replacements. Regular maintenance, such as gasket inspections and spark plug cleaning, can prevent these issues. Referencing the parts manual ensures correct part identification and repair procedures, minimizing downtime and ensuring reliable engine performance.

7.2 Diagnostic Techniques

Diagnosing issues in the Continental O-200 engine involves a combination of visual inspections, compression tests, and ignition system checks. Visual inspections can reveal oil leaks, corrosion, or worn components. Compression testing helps identify cylinder problems, while ignition checks ensure spark plugs and magnetos are functioning properly. Borescope inspections allow for internal examinations without disassembly. Listening for unusual sounds, like knocking or grinding, can pinpoint issues with bearings or valves. Regular monitoring of engine performance, including oil pressure and temperature, aids in early detection of potential faults. These techniques, guided by the parts manual, help technicians identify and address problems efficiently.

7.3 Repair and Replacement Guidelines

Repair and replacement of Continental O-200 engine components should strictly follow the parts manual’s instructions. Critical areas include crankcase inspection, cylinder replacement, and piston overhaul. Gasket sets must be installed correctly to ensure sealing integrity. When replacing parts, always use Continental-approved components or equivalent PMA parts. Torque specifications and assembly procedures must be followed precisely to avoid damage. Regular maintenance, such as spark plug replacement and oil changes, is essential for long-term reliability. Refer to the manual for specific tools and techniques required for each repair to ensure safety and performance. Proper documentation of repairs is also recommended for future reference.

Accessories and Optional Equipment

This section covers accessories and optional equipment for the Continental O-200 engine, including performance upgrades, installation guidelines, and compatibility with various aircraft models. Explore genuine parts, PMA replacements, and experimental components designed to enhance engine functionality and aircraft performance. Proper installation ensures safety, efficiency, and compliance with manufacturer standards. Refer to the manual for detailed specifications and support information to maintain optimal engine operation.

8.1 Available Accessories

The Continental O-200 engine supports a range of accessories and optional equipment to enhance performance and functionality. These include high-performance battery systems, cooling kits, and ignition components. Available accessories also feature lightweight starters, fuel pumps, and oil filters designed for optimal engine operation. Additionally, Continental offers PMA replacement parts and Titan experimental components for custom applications. These accessories are engineered to meet stringent quality standards, ensuring reliability and durability. Proper installation of these components is crucial for maintaining engine efficiency and compliance with manufacturer specifications. Explore the full range of accessories to tailor your engine setup to specific aircraft needs and performance requirements.

8.2 Installation and Compatibility

Proper installation of Continental O-200 engine accessories is critical for optimal performance and safety. Always follow the detailed procedures outlined in the parts manual to ensure compatibility and correct functionality. Accessories such as starters, generators, and fuel pumps must be installed according to manufacturer specifications to avoid operational issues. Compatibility with specific engine models, including C75, C85, C90, and O-200 series, should be verified before installation. Genuine Continental parts are recommended to maintain reliability and warranty compliance. Consult the manual or contact an authorized distributor for guidance on installing optional equipment and ensuring system integration. Proper installation ensures long-term engine reliability and performance.

8.3 Warranty and Support Information

Continental Motors offers comprehensive warranty coverage for genuine parts and accessories, ensuring customer satisfaction and product reliability. The warranty period varies by product, with detailed terms outlined in the parts manual. For technical assistance, customers can contact authorized Continental distributors or support centers. Genuine Continental parts are backed by a commitment to quality, with dedicated customer service available to address inquiries. Proper documentation and maintenance records are required for warranty claims. Continental’s global network provides timely support, ensuring minimal downtime and optimal performance for O-200 engine operators. This robust support system underscores Continental’s dedication to customer satisfaction and product excellence.

Continental Motors and Their Legacy

Founded in 1871, Continental Motors is a pioneering leader in automotive and aircraft engine manufacturing, renowned for innovation, quality, and reliability. Its legacy spans over 150 years, shaping aviation history with iconic engines like the O-200, trusted by pilots worldwide for their durability and performance. Continental’s commitment to advancing technology and customer satisfaction has solidified its reputation as a global leader in the industry.

9.1 History of Continental Motors

Founded in 1871 in Hanover, Germany, Continental Motors began as a rubber manufacturer, transitioning to automotive parts and later aircraft engines. By the 20th century, the company expanded into the U.S., becoming a key player in aviation. Continental developed the O-200 engine, a lightweight, efficient powerplant for small aircraft, solidifying its reputation in aviation. Over 150 years, the company has remained committed to innovation, quality, and reliability, earning its place as a global leader in engine manufacturing and automotive technology.

9.2 Commitment to Quality and Innovation

Continental Motors has consistently demonstrated a strong commitment to quality and innovation, ensuring its engines meet the highest industry standards. Through significant investments in research and development, the company has developed cutting-edge technologies that enhance engine performance and reliability. Advanced manufacturing techniques and rigorous quality control processes are integral to producing durable and efficient engines. This dedication to excellence has solidified Continental Motors’ reputation as a trusted leader in aviation engine technology, delivering solutions that meet the evolving needs of aircraft operators worldwide.

9.3 Global Reach and Reputation

Continental Motors boasts a global presence, with its engines and parts utilized by aircraft operators across the world. The O-200 series, in particular, has garnered international recognition for its reliability and performance. With a reputation for quality and innovation, Continental Motors has established a strong network of distributors and support centers, ensuring accessible service and parts availability worldwide. This extensive reach and trusted reputation have made Continental Motors a preferred choice for both general aviation and specialized aircraft applications, further cementing its legacy in the aviation industry.

10.1 Importance of Proper Maintenance

Proper maintenance is critical for ensuring the longevity, reliability, and safety of the Continental O-200 engine. Regular inspections, timely repairs, and adherence to manufacturers’ guidelines prevent premature wear and potential failures. The parts manual provides detailed procedures for routine checks, major overhauls, and parts replacement, ensuring compliance with aviation standards. By following these practices, operators can maximize engine performance, reduce downtime, and maintain compliance with regulatory requirements. Proper maintenance not only extends the engine’s lifespan but also ensures safe and efficient operation, making it a cornerstone of responsible aircraft ownership and operation.

10.2 Future of Continental O-200 Engines

The Continental O-200 engine remains a cornerstone of aviation, with a future driven by innovation and reliability. As aviation technology evolves, Continental Motors continues to develop advanced materials and designs, ensuring the O-200 series stays relevant. The parts manual serves as a vital resource, enabling technicians to maintain and upgrade these engines efficiently. With a strong focus on sustainability and performance, the O-200 engine is poised to meet future aviation demands, supported by Continental’s commitment to excellence and customer satisfaction. Its legacy as a dependable powerplant ensures its enduring presence in general aviation.

10.3 Final Thoughts on the Parts Manual

The Continental O-200 Parts Manual stands as an indispensable resource for anyone involved with these engines. Its detailed structure, comprehensive parts listings, and clear instructions make it a cornerstone for maintenance and repair. By adhering to the manual’s guidelines, users can ensure the longevity and performance of their engines. Continental’s commitment to quality is evident throughout, offering both practical and technical insights. Whether for routine maintenance or major overhauls, this manual provides the necessary tools to keep the O-200 running at peak efficiency, solidifying its reputation as a trusted reference in aviation engineering.